Umjikelo wamanzi umjikelo vacuum pump ukrola umatshini vacuum adsorption itheyibhile izixhobo eziyimfuneko, ukusetyenziswa vortex impompo yomoya ukufunxa ukulungisa ukunqunyulwa, ukwenzela ukuba ukusika kwinkqubo yokusika ayichanekanga, ukuqinisekisa ukuba ukuphakama ukusika ukuchaneka.

I-CNC router machine opener esetyenzisiweyo kumjikelezo wamanzi imodeli yamandla yempompo yempompo ngokuqhelekileyo yi-4.0KW, 5.5KW, 7.5KW, njl.

Umjikelo wamanzi vacuum adsorption impompo eziphambili amacandelo:

1. Izibuko lokufunxa:qhagamshela umbhobho we-adsorption womatshini wokukrola womthi.

2. Isigqubuthelo sothuli:thintela iitshiphusi zokhuni kunye nezinye i-sundries kwimpompo.

3. Khangela ivalve:misa impompo ukuthintela amanzi ukuba abuyele kwisixhobo.

4. Umbhobho wokungena kwamanzi:tofa ulwelo olusebenzayo kwimpompo ukuvelisa ivacuum.

5. Ivalve yokungena amanzi:lawula ukuhamba kwamanzi asebenzayo, ngaphambi kokuqala i-valve kufuneka ivulwe ngokupheleleyo, kwaye uqinisekise ukuba amanzi angenile kwimpompo, unokuqalisa ipompo yokucoca.

6. Indawo yokukhupha amanzi:Emva kweentsuku ezili-10 zokusetyenziswa, cima ulwelo olusebenzayo kwitanki yamanzi kwaye ubeke endaweni yalo ngamanzi acocekileyo athambileyo.

7. Ukukhupha izibuko:irhasi eveliswe kwinkqubo ye-adsorption ikhutshelwa emoyeni nge-exhaust port.I-port yokukhupha ayikwazi ukuvalelwa, ayikwazi ukudibaniswa kunye neemitha ezingaphezulu kweemitha ezimbini zombhobho, ayikwazi ukudibaniswa nobubanzi obungaphantsi kwe-5CM yombhobho, ngaphandle koko kulula ukuyilayisha, ukulimaza i-motor.

8. Umphakamo wamanzi aphezulu:yongeza amanzi kwitanki yamanzi de umphakamo wamanzi uthontsize ngaphandle, kwaye rhoqo wongeza amanzi phambi kokuba uqalise impompo yokufunxa yonke imihla ukuqinisekisa ukuba kukho ulwelo olwaneleyo lokusebenza (amanzi) kwitanki yamanzi.

9. Itanki yamanzi:ukubamba ulwelo olusebenzayo (amanzi).

Ngalo lonke ixesha uqala impompo yokufunxa, qiniseka ukuba kukho ulwelo olusebenzayo kwimpompo yokufunxa!Kwaye inqanaba lokusebenza kufuneka lifikelele ngaphezulu kwe-motor wheel shaft!

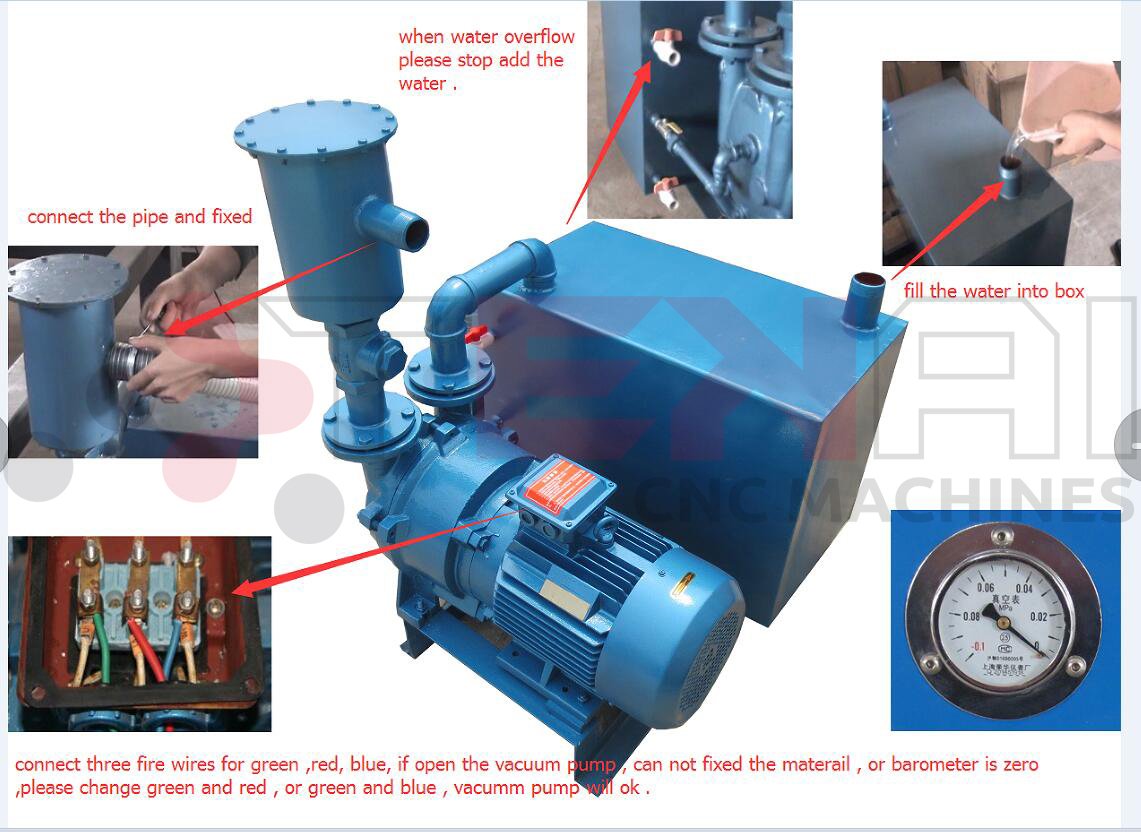

1. Izibuko lokufunxa lidityaniswe nombhobho we-adsorption womatshini wokukrola, kwaye itywinwe ngokungqongqo ukunqanda ukuvuza.

2. Isiqalo sokuqala, kunye ne-screwdriver toggle motor fan, ukuqinisekisa ukuba i-impeller ayibambekanga.

3. Qhagamshela unikezelo lwamandla ombane, kwaye ulungelelanise indlela yokusebenza ngokuhambelana nomgangatho.

4. Amanzi kwitanki yamanzi, de umlomo wamanzi uthontsize amanzi.

5. Vula ivalve yokutofa kwamanzi kwimpompo, kwaye ulinde imizuzu emithathu ukuqinisekisa ukuba ulwelo olusebenzayo luyangena kwimpompo.

6. Qala i-motor, i-vacuum pump iqala ukusebenza, itafile ye-adsorption ukuvelisa umphumo we-adsorption.Uvavanyo lwe-adsorption amandla.

7.Fakela isikhuseli somthwalo ongaphezulu kwemoto ukunqanda ukugcwala kwemoto ekutshiseni!!!!!!(Ingqalelo eyodwa)

Ukugcinwa kwempompo yokufunxa kumjikelo wamanzi

Kwinkqubo yokusebenzisa ipompo yokucoca umjikelezo wamanzi, ukuba kufunyaniswe ukuba ukufunxa akwanelanga kwaye isandi semoto siba lula, nceda uyeke kwangoko ukuze uhlolwe.

1. Jonga ngomonde ukuba ngaba umgangatho wamanzi wetanki yamanzi ungaphezulu kwesibini kwisithathu somphakamo wentloko yempompo yokufunxa.Ukuba iphantsi kakhulu, nceda wongeze amanzi ngoko nangoko.

2. Ukuba umgangatho wamanzi wetanki yamanzi uphezulu ngokwaneleyo, nceda ukhangele ukuba umbhobho wokungena kwamanzi phakathi kweentloko zempompo zetanki yamanzi uvaliwe, okubangela ukungabikho kwamanzi okwaneleyo.

3. Emva kokucoca kunye nokuzalisa izixhobo, qiniseka ukuba uvale i-air inlet emva kokuqala izixhobo, kwaye ulawule ukungena komoya ukuze uvumele amanzi okwaneleyo aqhubele kumzimba wempompo kwaye uvelise i-degree ye-vacuum eyaneleyo.

4. Coca itanki yamanzi, umbhobho wokungena kwamanzi kwaye utshintshe amanzi kwiintsuku ezingama-150 emva kokusetyenziswa kwempompo yokufunxa.Nceda uvale ivalve yokungena amanzi kwitanki yamanzi uze ukhuphe amanzi kumbhobho wokungena wamanzi.Ukuba ayisetyenziswanga ixesha elide, nceda ulawule kakuhle amanzi ngaphakathi kombhobho wamanzi kunye nentloko yempompo ukukhusela ukugqwala kunye nokuchaphazela ukusebenza.

5. Ukuba ayisetyenziswanga ixesha elide, ukuba kufunyaniswe ukuba i-motor ayikwazi ukusebenza emva kombane, kuyacetyiswa ukuba usebenzise iipliers zepayipi ukujikeleza i-shaft blade shaft emva kokunyanzeliswa, ukwenzela ukuba i-rust point yempompo. intloko ikhululiwe, ngoko ingasetyenziswa ngokuqhelekileyo.

Iingxaki eziqhelekileyo zempompo ye-vacuum yokujikeleza kwamanzi

1. Impompo yokufunxa ayicoci.

Esona sizathu:i-liquid esebenzayo ayizange ingene kwi-cavity yempompo, ayizange ifake umsesane wamanzi okanye ukuvuza komgca wokufunxa.

2. I-motor ayijiki xa i-vacuum pump iqalwa okokuqala.

Esona sizathu:Ngenxa yokuba ukucocwa phakathi kwe-impeller kunye ne-disk kuncinci kakhulu, iinxalenye zetsimbi ezifakwe i-oxidized, kwaye i-impeller outlet ibambelele.Esona sisombululo siphambili kukuvula isigqubuthelo sefeni yesiphelo esingasemva semoto, cofa i-axle yentloko engasemva yemoto ngehamile, emva koko ujikelezise i-motor blade ngesandla.Emva kokuqinisekisa ukujikeleza, faka i-fan cover kwaye uqale i-motor.

3. Ukufunxa impompo yokufunxa akwanelanga.

Esona sizathu:Ngaba ulwelo olusebenzayo alunelanga, khangela umbhobho wokungena kwamanzi;Umbhobho wokufunxa uyavuza.Jonga ukusebenza kokutywinwa kombhobho wokufunxa.Ulwelo olusebenzayo aluzange lutshintshwe ixesha elide, kwaye uthuli oluninzi lwamaplanga olungena kulwelo olusebenzayo luchaphazela umgangatho wolwelo olusebenzayo, ngoko ke kuyimfuneko ukunikela ingqalelo ukugcina ulwelo olusebenzayo lwamanzi acocekileyo.

4. Ingxolo yempompo yokufunxa.

Esona sizathu:Ngaba zonke iivalve kumbhobho wokufunxa zivaliwe.Ukupompa ipompo ye-vacuum ifikelela kumda wayo, kwaye isandi sokuguguleka kwe-cavitation senziwa.Ingxolo yevalve yombhobho wokungena iya kunyamalala xa ivulwa.

Qala kwiinkcukacha, ngokweemfuno zokusebenza okusemgangathweni kunye nokusetyenziswa, umatshini ungasetyenziselwa ixesha elide.

© Copyright - 2010-2023 : Onke Amalungelo Agciniwe.

Iimveliso ezishushu - Imephu yesiza