Iphampu ye-vacuum yomjikelezo wamanzi iqopha itafula lomshini we-vacuum adsorption imishini edingekayo, ukusetshenziswa kwe-vortex air pump suction ukulungisa ukusika, ukuze ukusika enqubweni yokusika kungasuswa, ukuqinisekisa ukuthi ukuphakama kokusika ukunemba.

I-CNC router machine opener esetshenziswa umjikelezo wamanzi wepompo yamamodeli wamandla ngokuvamile angu-4.0KW, 5.5KW, 7.5KW, njll., amandla ahlukene we-vacuum adsorption amandla nawo ahlukile.

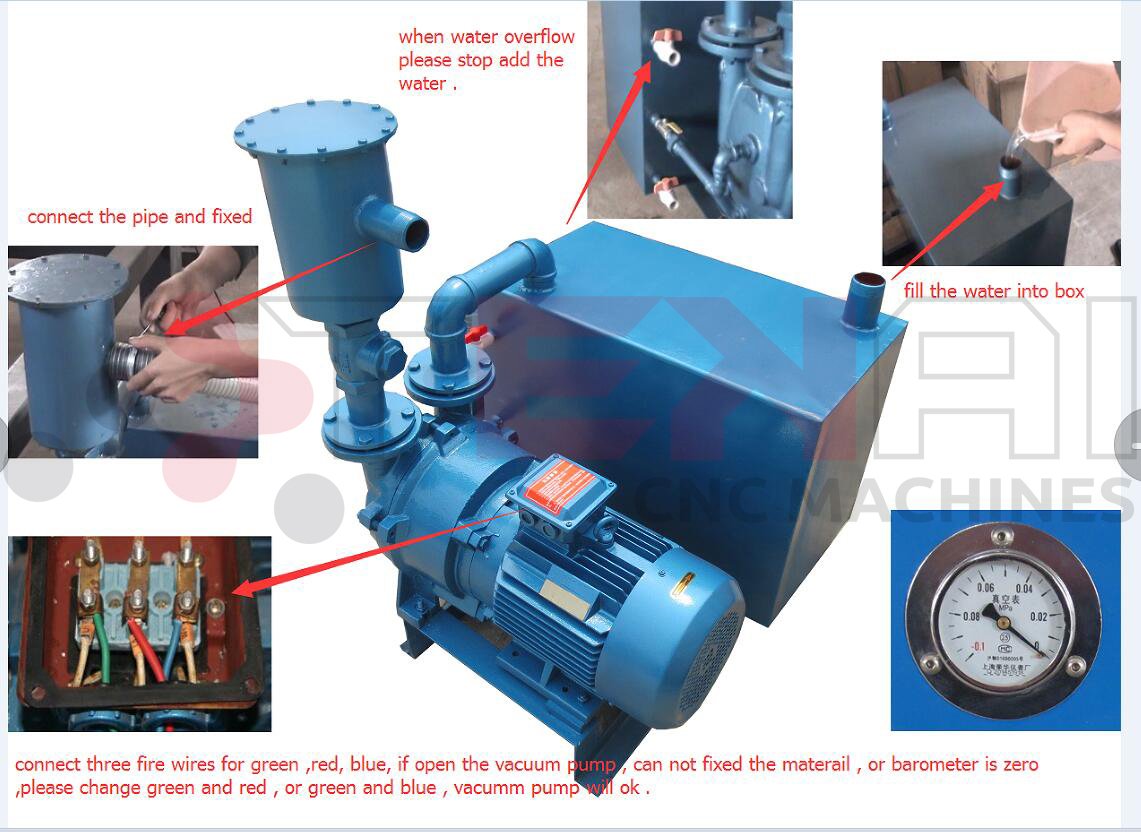

Izingxenye eziyinhloko zephampu ye-vacuum yomjikelezo wamanzi:

1. Imbobo yokudonsa:xhuma ipayipi le-adsorption lomshini wokuqopha wokhuni.

2. Ikhava yothuli:vimbela izingcezu zokhuni nezinye i-sundries empompini.

3. Hlola i-valve:misa iphampu ukuvimbela amanzi ukuthi abuyele emshinini.

4. Ipayipi elingenisa amanzi:faka uketshezi olusebenzayo epompo ukuze kukhiqizwe ivacuum.

5. Ivalvu yokufaka amanzi:lawula ukugeleza kwe-liquid esebenzayo, ngaphambi kokuqala i-valve kumele ivuleke ngokuphelele, futhi uqinisekise ukuthi amanzi angenile epompo, angaqala ipompo ye-vacuum.

6. Indawo yokukhipha amanzi:Ngemuva kwezinsuku ezingaba ngu-10 zokusetshenziswa, khipha uketshezi olusebenzayo ethangini lamanzi bese ufaka amanzi ahlanzekile athambile esikhundleni salo.

7. Imbobo yokukhipha umoya:igesi ekhiqizwe kunqubo ye-adsorption ikhishelwa emkhathini ngembobo yokukhipha umoya.Imbobo yokukhipha umoya ayikwazi ukuvinjwa, ayikwazi ukuxhunywa ngamapayipi angaphezu kwamamitha amabili, ayikwazi ukuxhunywa ngobubanzi obungaphansi kwepayipi le-5CM, ngaphandle kwalokho kulula ukulayishwa kakhulu, kulimaze injini.

8. Izinga lamanzi eliphezulu:engeza amanzi ethangini lamanzi kuze kuphume izinga eliphezulu lamanzi, bese wengeza njalo amanzi ngaphambi kokuqala ipompo yokuhlanza nsuku zonke ukuze uqinisekise ukuthi kunoketshezi olusebenzayo olwanele (amanzi) ethangini lamanzi.

9. Ithangi lamanzi:ukubamba uketshezi olusebenzayo (amanzi).

Ngaso sonke isikhathi uma uqala ipompo yevacuum, qiniseka ukuthi kunoketshezi olusebenzayo empompini yevacuum!Futhi izinga lokusebenza kufanele lifinyelele ngaphezu kwe-motor wheel shaft!

1. Imbobo yokudonsa ixhunywe nepayipi lomshini wokuqopha i-adsorption, futhi ivalwe ngokuqinile ukuvimbela ukuvuza.

2. Isiqalo sokuqala, esine-screwdriver toggle motor fan, ukuqinisekisa ukuthi i-impeller ayibambeki.

3. Xhuma ukunikezwa kwamandla emoto, futhi ulungise isiqondiso sokusebenza ngokuhambisana nezinga.

4. Nisela ethangini lamanzi, kuze kube yilapho umlomo wamanzi ongaphezulu uconsa amanzi.

5. Vula ivalvu yokujova amanzi empompini, bese ulinda imizuzu emithathu ukuze uqinisekise ukuthi uketshezi olusebenzayo lugelezela epompo.

6. Qala injini, iphampu ye-vacuum iqala ukusebenza, ithebula le-adsorption likhiqiza umphumela we-adsorption.Hlola amandla e-adsorption.

7. Faka isivikeli se-motor overload ukuvimbela ukugcwala kwemoto ukuthi kungashi !!!!!!(Ukunakwa okukhethekile)

Ukulungiswa kwephampu ye-vacuum yomjikelezo wamanzi

Enqubweni yokusebenzisa iphampu ye-vacuum yomjikelezo wamanzi, uma kutholakala ukuthi ukudonsa akwanele futhi umsindo wemoto uba lula, sicela ume ngokushesha ukuze uhlolwe.

1. Bheka ngesineke ukuthi ingabe izinga lamanzi ethangini lamanzi lingaphezulu kwezingxenye ezimbili kwezintathu zobude bekhanda lepompo levacuum.Uma liphansi kakhulu, sicela wengeze amanzi ngokushesha.

2. Uma izinga lamanzi ethangini lamanzi liphakeme ngokwanele, sicela uhlole ukuthi ipayipi lokungena lamanzi phakathi kwamakhanda epompo ethangi lamanzi livimbekile, okuholela ekutheni amanzi anganele.

3. Ngemva kokuhlanza nokugcwalisa okokusebenza, qiniseka ukuthi uxhuma i-air inlet ngemva kokuqala okokusebenza, futhi ulawule ukungena komoya ukuze uvumele amanzi anele ageleze emzimbeni wepompo futhi ukhiqize i-vacuum degree eyanele.

4. Hlanza ithange lamanzi, ipayipi elingenisa amanzi bese ushintsha amanzi zingakapheli izinsuku eziyi-150 ngemva kokusetshenziswa kwephampu yevacuum.Sicela uvale ivalvu yokungena amanzi ethangini lamanzi bese uthulula amanzi epayipini elingenisa amanzi.Uma ingasetshenziswa isikhathi eside, sicela ulawule kahle amanzi ngaphakathi kwepayipi lamanzi kanye nekhanda lepompo ukuvimbela ukugqwala futhi kuthinte ukusebenza.

5. Uma ingasetshenzisiwe isikhathi eside, uma kutholakala ukuthi i-motor ayikwazi ukugijima ngemuva kokukhanyisa amandla, kunconywa ukusebenzisa amapayipi amapayipi ukuze ujikeleze i-shaft blade emva kwamandla, ukuze iphuzu lokugqwala lepompo. ikhanda liyathukululwa, bese lingasetshenziswa ngokujwayelekile.

Izinkinga ezivamile zephampu ye-vacuum yokujikeleza kwamanzi

1. Iphampu yevacuum ayicimi.

Isizathu esiyinhloko:uketshezi olusebenzayo aluzange lungene emgodini wepompo, aluzange lufake indandatho yamanzi noma ukuvuza komugqa wokudonsa.

2. Injini ayijiki lapho ipompo yevacuum iqalwa okokuqala.

Isizathu esiyinhloko:Ngenxa yokuthi imvume phakathi kwe-impeller ne-disk incane kakhulu, izingxenye ze-cast iron zi-oxidized, futhi i-outlet ye-impeller ibambekile.Isixazululo esiyinhloko ukuvula ikhava yabalandeli yokuphela kwenjini, uthephe i-axle engemuva yekhanda ngesando, bese uzungezisa i-motor blade ngesandla.Ngemuva kokuqinisekisa ukuzungezisa, faka ikhava yabalandeli bese uqala injini.

3. Ukumunca iphampu yevacuum akwanele.

Isizathu esiyinhloko:Ingabe uketshezi olusebenzayo alwanele, hlola ipayipi lokungena kwamanzi;Ipayipi lokumunca liyavuza.Hlola ukusebenza kokuvala kwepayipi lokumunca.Uketshezi olusebenzayo aluzange luthathelwe indawo isikhathi eside, futhi uthuli oluningi lwezinkuni olungena oketshezini olusebenzayo luthinta ikhwalithi yoketshezi olusebenzayo, ngakho-ke kuyadingeka ukunaka ukugcina uketshezi olusebenzayo lwamanzi ahlanzekile.

4. Umsindo wepompo ye-vacuum.

Isizathu esiyinhloko:Ingabe ukuthi wonke ama-valve epayipi lokumunca avaliwe.Ipompo yokumpompa ivacuum ifinyelela umkhawulo wayo, futhi umsindo wokuguguleka kwe-cavitation uyakhiqizwa.Umsindo we-valve yepayipi yokungena uzonyamalala uma ivulwa.

Qala kusuka emininingwaneni, ngokuya ngezidingo zokusebenza okujwayelekile nokusetshenziswa, umshini ungasetshenziswa isikhathi eside.

© Copyright - 2010-2023 : Wonke Amalungelo Agodliwe.

Imikhiqizo Eshisayo - Imephu yesayithi